From Concept to Completion

Smart material handling and racking systems to fit your facility and process

Here’s the Key to Preventing Pallet Rack Forklift Damage…

Simple Steps You Can Take to Protect Your Equipment, Product and Employees

Pallet rack safety and pallet rack functionality go hand in hand. From concept to installation to implementation the safety of your rack system is paramount. Some pallet rack systems inherently combine safety and functionality; think of the cant leg frame, but often safety features are added to a rack system for additional protection for employees, products and the rack investment itself. Additionally, steps can be taken within the warehouse environment and with warehouse machinery to further ensure that the business of product fulfillment operates as smoothly and effectively as possible.

Full consideration of the intended use of your rack system must be provided when developing the layout. What type of products will be stored, weight and dimension, as well as expected fulfillment and restocking rates and warehouse equipment. Abuse resistant design elements such as cant leg frames can be designed right into the system at that time if there is a concern for aisle clearance and truck maneuverability. To complete an effective rack system design, proper safety guard features can be included from the start or added at anytime to prevent rack, equipment and facility damage. These products are often the brightly colored protection elements secured onto and around the pallet rack.

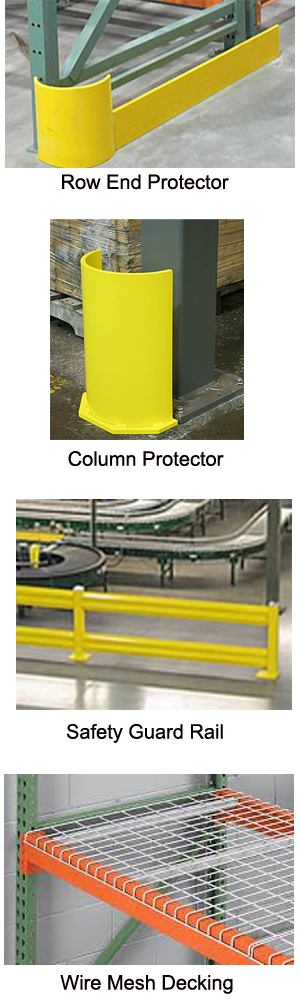

Pallet Rack Safety & Damage Resistance Accessories:

- Row End Rack Protectors – placed at the end of the aisle to protect against forklift abuse

- Column Protectors – come in varying shapes and configurations to provide additional support to front columns

- Rub Rails – bolted into the frames horizontally (below the lowest horizontal beam) to redistribute impact forces from the front column to the rear and to keep the column from rotating when hit

- Rack Safety Netting – attached directly to rack and/or railings prevents falling product and debris

- Wire Mesh Decking – add strength and safety to traditional pallet rack configurations

- Safety Guard Rails – can be positioned around racks and machines to protect against fork truck abuse and provide traffic flow

- Proper Rack Weight and Capacity Signage – proved by the rack manufacturer and specific to the rack systems in use… must be placed in clearly visible locations

In the inimitable words of Benjamin Franklin, “An ounce of prevention is worth a pound of cure.” While he may not have been speaking directly about warehouse safety…his words stand today. Since the forklift is the main culprit in rack damage, ensure that all operators are trained according to the guidelines established by OSHA. Ensure that the appropriate forklifts are being used for the tasks and warehouse environment. In addition, set challenging, yet reasonable expectations for drivers so they can meet their mark without endangering themselves or others. The money spent on a safe work environment will come back multi-fold in return on investment so perhaps consider some less often thought of measures to increase safety and profitability.

Additional Safety Steps:

- Bright colored paint for the forklift forks

- Forklift safety accessories – panoramic forklift mirrors, auto park brakes, flashing lights and backup or motion alarms

- Rack-mounted safety mirrors

Equally important to the design and construction of the system is the maintenance. Conduct regular (weekly/monthly) rack inspections paying careful attention to rack condition and bolted connections. Also, resist the urge to alter the configuration of the pallet rack system yourself. Even what may seem like simple changes in shelf elevation could change the column capacity. In situations where pallet racks need repair or re-purposing it is always advised to contact the professionals.

The time and money spent protecting your pallet racks from structural damage will be well worth the investment when the time comes to resell existing rack or prepare for upgrades and warehouse reorganization.

Remember, call E-Distribution We’ll help define all of your rack safety requirements. We can also conduct a quick walk-through to make recommendations or schedule a project or system audit at your convenience.