From Concept to Completion

Smart material handling and racking systems to fit your facility and process

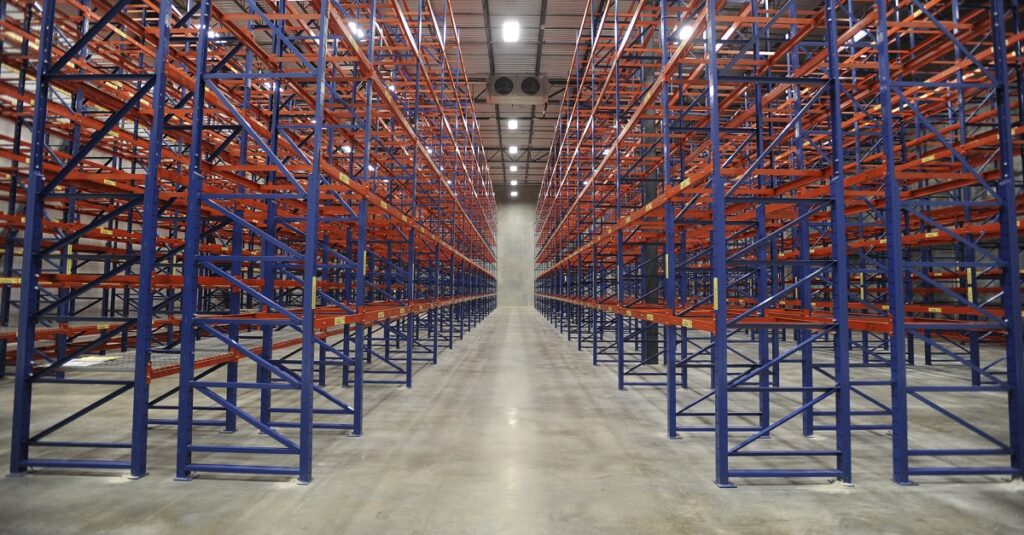

Give Me Some Space… For Safe & Productive Warehouse Operations

Whether building new or remodeling an existing distribution center, configuring the warehouse space that will not have storage rack is equally as important as the area that will. Here’s why… while pallet and case storage rack is designed intentionally to consolidate inventory and maximize warehouse space and efficiency, the area around the racking where people and equipment maneuver also has a direct impact on productivity. So, let’s take a closer look at those important space considerations from a system layout and installation perspective.

Aisle space

Aisle width is predicated on the type of storage rack system and the vehicle or pedestrian interface that will be loading and retrieving inventory from the system.

Pick Aisles & Pedestrian vs Equipment Interface

Pick Aisles & Pedestrian vs Equipment Interface

Pick aisles are designed as areas where workers retrieve cases or single items from typically selective rack, shelving or carton flow systems. In simple pick aisles, the open space can be more narrow to accommodate workers only. However, case pick rack can also include full-pallet storage below or above the pick area. In such circumstances the surrounding aisle width must be designed to accommodate vehicle traffic for pallet loading vs simply pedestrian workers.

If the pick aisle is flanked by take away conveyor, the rack and conveyor systems need to be mounted within a comfortable, and preferably ergonomic, range for the workers to pick then load with minimal worker strain supporting a productive order picking operation.

Forklift Interface

Pallet rack that is loaded and unloaded from a single aisle via forklift defines selective, drive-in, push-back, cantilever or even some ASRS pallet storage systems.

Aisle space designed to accommodate vehicle traffic can be categorized into 3 major buckets:

Aisle space designed to accommodate vehicle traffic can be categorized into 3 major buckets:

- Wide aisles > 10′

- Narrow aisles = 9’

- VNA (very narrow aisles) < 9’

Sometimes it’s tempting to use a standard 12’ measurement, however, significant space savings can be garnered… 3’-6’ of space in some cases, when the aisle is designed more specifically to the equipment that will used. It is recommended to consult with the forklift supplier and obtain the equipment specs and calculations early in the material handling systems design phase.

4-Step to Allocate Warehouse Aisle Space

- Determine “head” length of the forklift (from back of truck to front of load back rest)

- Add load length – length of pallet

- Add additional 6” for pallet overhang (could be more with oversized pallets)

- Add 12” for forklift maneuverability

Flue Space

Flue space is another important “space” consideration for rack design and installation. The flue area is the area between the backs of two pallet rack systems… often referred to as back-to-back rack. The pallet rack systems do not actually touch, and instead they are secured with row spacers (steel bars, channels, or rods) that connect the two systems for stability. The open area between the rack must remain free of inventory or material in order to comply with fire safety and allow the most effective sprinkler use.

Don’t Space Out… Hire Professional Rack Installers

Don’t Space Out… Hire Professional Rack Installers

One of the best ways to ensure your warehouse is ready for the non-stop, frenetic pace of warehouse storage and distribution is to hire licensed, professional pallet rack installers like the team from E-Distribution. Professional rack installation crews understand system mechanics, know how to avoid difficulties and equally as important they can effectively troubleshoot challenges if and when they occur. Call today to schedule a warehouse consultation or pallet rack system installation and give your operations all the space needed to optimize productivity and ROI.